Non-Destructive Testing

Non-Destructive Testing – Designed to See What You Can’t

Non-destructive testing (NDT) refers to a wide group of inspection methods used to analyze the soundness of a material, component, or structure without physically or chemically altering it. American Testing Services offers a comprehensive array of conventional and advanced NDT capabilities and perform visual inspection in conjunction with all of our test methodologies.

American Testing Services offers Non-Destructive Testing and Non-Destructive Inspection services on your schedule. When necessary, our labs can operate 24/7 to accommodate your timeline.

American Testing Services’ NDT methods are available both in our facility and in the field. Our team is trained in proper safety procedures for field inspections including fall protection, confined space, and personal protective equipment.

Whether you need standard Non-Desctructive Inspection and Non-Destructive Testing Services or you need a custom NDT soulution, American Testing Services is your source for Non-Destructive Testing you can trust. Contact American Testing Services today, and let our team give you the piece of mind you deserve!

Our Testing Capabilities

Bolt Torquing

Bolt torquing is an important part of ensuring mechanical fastenings are performing efficiently and safely on large structures or equipment. These structures may include thousands, if not millions, of individual bolts that require regular testing to ensure the structural integrity of your product and negate any potential signs of weakness. Bolt torquing is performed on location and may be performed in conjunction with our industrial rope access services.

At American Testing Services, our personnel are able to accommodate all bolt and fastener sizes and currently, we have the capability to apply up to 10,000 PSI, producing 3230 foot-pounds in torque value.

Certified Weld Inspector Services (CWI)

The American Welding Society created the Certified Weld Inspector program to accredit welding inspectors at the highest standards. The intentions were to ensure that anyone using this inspection specification for welding and welding oversight received the highest quality craftsmanship expected from a given engineering design for a welded part or project.

AWS-CWI services cover a wide range of welding inspection requirements. Unlike traditional non-destructive inspections, CWI services can start prior to any welding operations. In some cases, this service is a complete oversight of a welding or fabrication project – verifying, documenting, and reporting per the given requirements. This can include welder certifications, material certifications, and welding filler material certifications. Additional requirements could include verifying and documenting weld prep, weld pre-heat / post-heat, machine settings, equipment calibrations, monitoring weld sizes, and visual inspections as the work progresses. Additional NDT might also be included during and/or after all welding operations are complete. A comprehensive report with all of the required documentation is presented to the customer upon the welded part or project completion.

Contact American Testing Services if you have a project requiring CWI services or if you’re quoting a weld project with CWI requirements. We can walk you through the steps to ensure all of your customer’s needs are met. It is important to engage early on any project with a CWI requirement to avoid a costly situation for you and your customer if important milestones in the process are skipped.

Eddy Current

Utilizing electromagnetic induction in any conductive material, eddy current inspections can detect small defects in a variety of components, while also being able to provide material or coating thickness measurements. This test method is excellent for research and development applications.

Our highly trained technicians can analyze results from specialized testing equipment using advanced software, minimizing downtime in the manufacturing or repair processes and decreasing inspection costs. At American Testing Services, experienced inspectors can provide an array of quality information ranging from simplistic thickness measurements and material conductivity or complex analysis with aerospace engineering materials.

Liquid Penetrant

Liquid penetrant inspection is appropriate for finding discontinuities that are open to the surface, such as cracks, laps, and seams. It is a very popular method because of its low cost and portability. It can be used on a wide variety of materials, as well as various sizes and shapes. The dye is capable of entering very small defects that would not be detectable by the human eye alone.

At American Testing Services we are capable of performing both fluorescent and visible dye inspection methods, using water washable and post-emulsified applications. These inspections can be performed in-house at our lab or out in the field.

Magnetic Particle

Magnetic particle inspection is used for locating discontinuities on the surface and slightly subsurface in ferromagnetic objects. It is able to be used on a wide variety of materials, as well as various sizes and shapes. Magnetic particle inspection is very economical and provides instantaneous results. Similar to liquid penetrant inspection, it is capable of making very small linear discontinuities, cracks, laps, or seams visible to the human eye for detection.

Our certified technicians are able to perform both fluorescent and visible magnetic particle inspection methods. At our lab or on-site, we can inspect a wide range of materials.

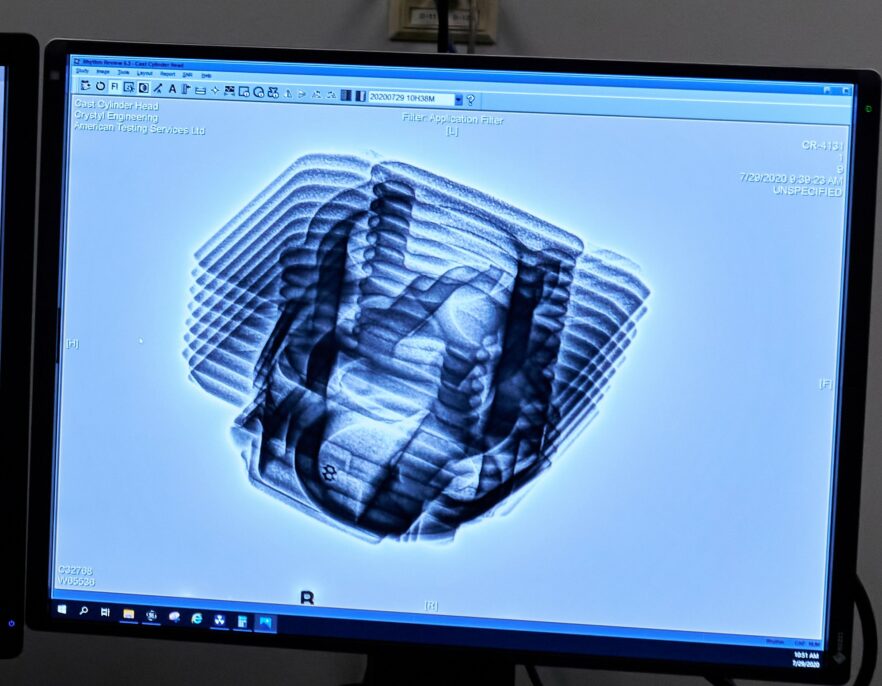

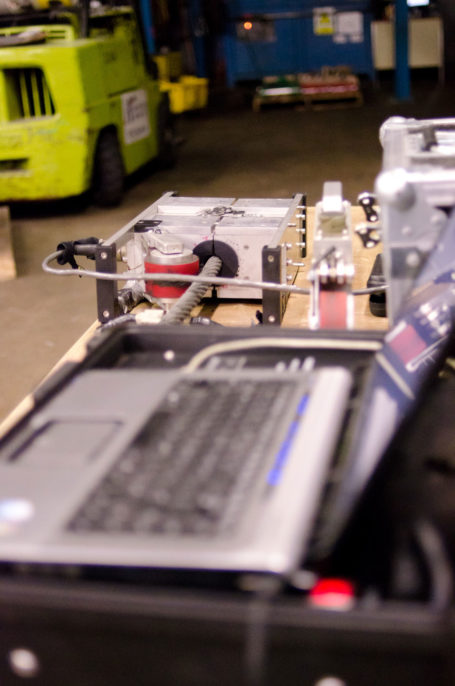

Radiography/Computerized Radiography

Radiographic inspection uses X-rays to perform a volumetric assessment of raw materials, such as castings and finished components. This method can be performed in our lab conventionally with film or by providing computerized images for analysis and interpretation.

Our computerized radiography inspection services provide many advantages over film radiography because we are able to achieve high resolution images with faster shot times, eliminate the need for film and chemicals, and increase reliability and repeatability. Our highly trained technicians are able to use advanced software tools that allow defects to be accurately detected and measured.

Ultrasonic

Ultrasonic inspection uses the transmission of high frequency sound waves into a material to detect imperfections within the material or changes in material properties. Ultrasonic inspection is utilized to perform volumetric inspections on raw materials, as well as in process components and finished materials. Ultrasound can be used on a variety of materials from exotic metals to composite structures.

In addition to performing contact inspections at our lab or in the field, our certified technicians can provide 100% full volumetric inspection using one of our automated 6-axis immersion ultrasonic systems. Our immersion systems have the capabilities to perform precise automated scanning and critical inspection for the detection of a variety of defects within a part, including cracks, voids, delaminations, and many others.

Visual Inspection

Visual inspection is the most widely used non-destructive testing (NDT) method in the world. Nearly everyone in the industry uses visual inspection on a daily basis. It has been proven that a properly trained individual is at least two times as likely to find the sought-after results. All parts are visually inspected prior to performing other NDT methods.

At American Testing Services, we have the training and expertise to help save time and money. Our experienced visual inspectors approach each job with a deep understanding of the applicable code requirements, products and material processes, anticipated service conditions, and the acceptance criteria.

Wire Rope

Wire rope inspection is a computerized, electromagnetic test of ferrous wire ropes. It detects and measures localized defects or deterioration and loss of material. This method is capable of analyzing both internal and external flaws. Our test method is capable of measuring relative changes in average metallic area of 0.1% and of detecting flaws to 0.05% of nominal rope area.

Dedicated to Safety

- All of our business is conducted in accordance with OSHA regulations. We have an excellent safety record with few lost time incidents.

- Our rope access technicians are independently trained and certified through SPRAT (Society of Professional Rope Access Technicians) every 3 years, which includes high angle rescue procedures.

- SPRAT membership provides our technicians with access to the latest standards, equipment, and tools.

- Rope access is statistically safer than scaffolds and uses fewer workers.

- We require a minimum of two technicians for all rope access work, enabling mutual surveillance.

- Our technicians work from two ropes – a working rope and a safety rope. Each rope is independently anchored, and the technician is permanently attached to both.

- Rope systems can be removed from a job site at the end of each shift, minimizing the chance of vandalism.

Non-Destructive Testing vs. Metallurgy

NDT shows you what you need to see without breaking it. Metallurgy breaks it so you know how, why and where it’s possible to fail. Arm yourself with the knowledge you need to know, before you need to know it.

American Testing Services Offers Full Spectrum Solutions to Provide You With the Peace of Mind You Need.

To complement our non-destructive testing, we also provide consulting, equipment calibrations, and training.

NDT Consulting

NDT Equipment Calibrations