You know that your parts require some kind of non-destructive testing inspection, but do you know what is happening to your parts when that test method is applied? Over the next few weeks, our level III technicians will provide an explanation of each NDT method we employ along with some advantages and limitations of each.

In this post, we’ll discuss Liquid Penetrant testing.

Liquid Penetrant inspection (PT) is a non-destructive testing method that uses both fluorescent and red dyes to allow surface defects of a given material to be more easily seen by the inspector. This NDT inspection method can be performed on a variety of components, including various metal alloys, plastics, composites, fired ceramics and glass.

Liquid Penetrant inspection (PT) is a non-destructive testing method that uses both fluorescent and red dyes to allow surface defects of a given material to be more easily seen by the inspector. This NDT inspection method can be performed on a variety of components, including various metal alloys, plastics, composites, fired ceramics and glass.

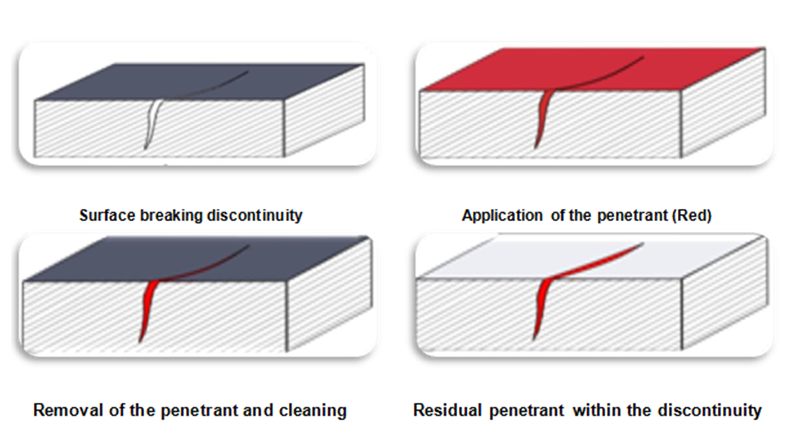

Penetrant is applied to a clean material and allowed to dwell for a specified amount of time. During this dwell time, penetrant is forced into any surface abnormalities via capillary action. Capillary action is the ability of a liquid to absorb into a narrow passageway (defect). This capillary action is the result of the adhesion of the material being stronger than the cohesive force between the liquid molecules.

Have you ever place a drinking straw into a liquid and wondered why the liquid in the straw is higher than the liquid in the glass? This is capillary action at work. Another example of capillary action is when the wick on a kerosene lamp is able to absorb the kerosene stored in the base of the lamp. This works without the assistance of external forces, such as gravity.

Once penetrant has been allowed to dwell on the component, the majority of the penetrant is rinsed off of the surface. Rinsing can be accomplished by using lint free towels dampened with solvent or via a water rinse.

After excess penetrant is removed from the surface, the component is dried. Once the component is dry, a developer is applied. The developer draws penetrant out of any defects and forms an indication, commonly known as bleed-out or reverse capillary action. Similar to the penetrant, the developer is allowed to dwell for a specified amount of time.

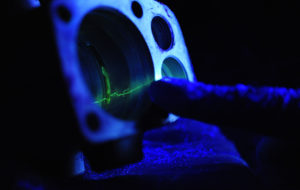

Once development is complete, inspection can begin. If fluorescent dye penetrant was used, the component is inspected with the aid of a black-light. If visible red dye penetrant was used, a white light can be used for inspection.

If any indications are discovered, the inspector must determine if they are due to defects in the material or if they are non-relevant indications. The inspector references a code or standard to determine whether or not an indication would interfere with the serviceability or purpose of the component. The component is then accepted or rejected based on the requirement of the code or standard.

Contributed by:

Ben Graves

Liquid Penetrant Level III Technician