You know that your parts require some kind of non-destructive testing inspection, but do you know what is happening to your parts when that test method is applied? Over the next few weeks, our level III technicians will provide an explanation of each NDT method we employ along with some advantages and limitations of each.

We continue this series with Magnetic Particle testing.

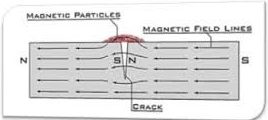

Magnetic Particle testing (MT) is a form of non-destructive testing that uses magnetism induced into a ferromagnetic object to detect flaws.

testing (MT) is a form of non-destructive testing that uses magnetism induced into a ferromagnetic object to detect flaws.

When an electrical current is passed through a ferromagnetic object, a magnetic field is produced. If there is a disruption to this magnetic field, such as a crack, a flux leakage field is formed at the location of the crack. When ferromagnetic particles are applied to the object, they will collect in this leakage field and give the inspector an enhanced visible indication of the crack.

The ferromagnetic particles applied can be fluorescent and used in conjunction with a black light to make them visible to the naked eye. Particles may also be dyed various colors, such as red or gray, allowing them to be seen under normal lighting conditions.

The ferromagnetic particles applied can be fluorescent and used in conjunction with a black light to make them visible to the naked eye. Particles may also be dyed various colors, such as red or gray, allowing them to be seen under normal lighting conditions.

Magnetic Particle testing requires the use of specialized equipment and chemicals that provide immediate, visually identifiable results of the integrity of an object. It will detect indications on the surface and slightly subsurface levels.

Contributed by:

Ben Graves

MT/PT Level III Technician & CWI