Have you noticed all of the new businesses being built in the Greater Dayton area? Even older companies that have been around for a number of years are improving their existing facilities or building new ones.

What does all this mean? Expanding construction is a good sign the economy is turning around, money is being invested, and jobs are being created.

One very important job in the construction industry is welding. It’s a key element whether your perspective is a fabrication shop welding on beams and girders, on the job site tying all the parts and pieces together, or connecting the piping going to and from the buildings. Most companies in the construction industry (and others) require that their welders be certified.

There are no defined prerequisites to becoming a certified welder. If you have a background in welding, you are able to deposit sound weld metal for a specific certification test, and you pass all the requirements, you can become certified in that method.

There are no defined prerequisites to becoming a certified welder. If you have a background in welding, you are able to deposit sound weld metal for a specific certification test, and you pass all the requirements, you can become certified in that method.

Certification must be performed via practical testing administered by an approved testing facility, such as Hobart Institute of Welding Technology (HIWT) in Troy, Ohio. HIWT also provides training for personnel who don’t currently have a background in welding.

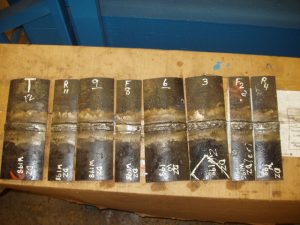

Once you have completed your welded test coupon(s), it will first be evaluated visually for defects such as cracks, porosity or overlap. The welds are then tested by a non-destructive method. This might include radiography for internal defects and/or liquid penetrant evaluation for defects open to the surface, such as excessive porosity, incomplete penetration of the weld through the components being joined, and incomplete fusion of the weld material to each component.

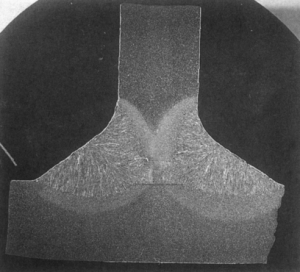

Some welds, such as fillet welds (where two components are welded at right angles), cannot be evaluated by non-destructive testing and must be sectioned, polished and etched to examine them metallographically. At the conclusion of testing, the results are compared to the requirements of the weld procedure and welding specification to determine if the welder can be certified.

Some welds, such as fillet welds (where two components are welded at right angles), cannot be evaluated by non-destructive testing and must be sectioned, polished and etched to examine them metallographically. At the conclusion of testing, the results are compared to the requirements of the weld procedure and welding specification to determine if the welder can be certified.

Once you are certified in welding, a vast number of opportunities are opened up for your future. Just remember, the only things separating you from any career you decide to follow are: Training, Tools, and Experience. With these three simple things, you can do anything.

Contributed by:

Ben Graves Doug Evenden

AWS Certified Weld Inspector Metallurgist

& NDT Level III